| String

instruments have three main parts:

1)

the body, where the sound's resonance is produced,

shaped and intensified;

2)

the neck, which has stretched strings that pass over

the resonant body-these strings are pressed down with

the fingers of the left hand in order to produce sounds

of various pitches; and

3)

the head, which has pegs that hold the ends of the

strings and are used for tuning the instrument.

|

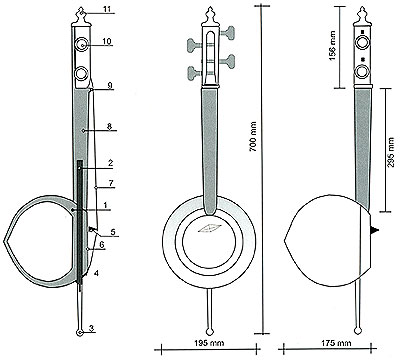

1.Body.

2.Pivot. 3.Stand. 4. String holder. 5. Big stand.

6. Back

7. Strings. 8.Neck. 9.Small stand. 10. Pins. 11.Head. |

|

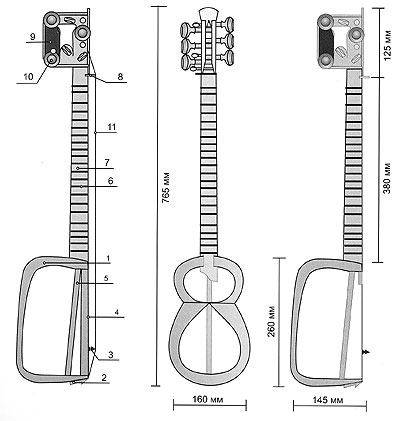

1.Body.

2.String holde. 3. Bi stand. 4. Back. 5.Pivot.

6.Frest.

7. Neck. 8.Small stand. 9.Head. 10. Pins. 11.

Strings |

There

are two types of technology for making the body of

a string instrument:

1) A method of assembly in which the various parts

of the instrument are made separately and then put

together. The ud, saz, barbat, choghur, chagane, santur

and ganun are made in this way.

2) A method of hollowing out a tree stump from the

inside and polishing it from the outside to create

the required form. The tar, kamancha, rud, rubab,

tanbur, gopuz and chang are made in this way.

For the first method, first a special form is made.

An element called a "kup" is placed on the

upper part, and another called a "dabanjig"

is placed on the bottom of the form. Dried wood is

cut into five-mm-thick lags of the appropriate sizes.

These lags are soaked in hot water (70-90 C) for 20-25

minutes, bent in the form and installed on the kup

and dabanjig.

The lags are fixed with the help of metal clips. The

number of lags is usually odd (9 or 1 1).

Next, the neck is fixed to the finished body. It is

important to make sure that the body corresponds to

the neck. There should be a five-mm gap at the juncture

of the body and neck. This gap is left to fix the

neck in position after straining the strings. A special

rule is used to be exact in defining this space.

After fixing the body and neck together, the sounding

board is added. The sounding board is made of mulberry

or nut wood. The thickness of the sounding board is

five mm. It is greased with linseed oil or another

vegetable oil and left for several days. Once the

wood absorbs the oil completely, it is dried on the

fire. Several days later, this procedure is repeated

again. The finished sounding board is attached to

the body using special wood glue made from cod liver

oil. Separate pieces are polished and cleaned. Then

a hot glue is placed on them. The parts are assembled

and tightly pressed together. Next, pegs and frets

are fixed to the instrument.

For the second method, the artisan has to take into

account the season in order to determine when the

tree should be cut down. The trees' level of gumminess

usually goes down in January and February. The tree

has to be cut down at this time, since a body made

of wood with a high gum level always chaps or warps

after drying. After the body is hewed out, it should

be allowed to dry.

In order to make the body of the instrument, the tree

trunk that is cut out should be bisected and the core

should be taken out. The surfaces of the two pieces

are polished. Then, the contours of the instrument

are drawn on the pieces so that they can be hollowed

out along these contours. The mulberry tree should

be hollowed out when the wood is still wet. Practice

shows that an old and cored tree is not good for making

the body of a music instrument.

The sounding of the instrument depends greatly on

how it has been assembled. After the body is dried,

the inner and outer parts are hewed and polished again.

Then the neck, head and other parts of the instrument

are fixed to the body. A film made from bull heart

or fish skin is stretched over the body. A large bridge

situated inside the body receives the vibration of

the strings and transfers it to the inner cavity of

the body. The acoustic waves that are generated in

this cavity flow out again. The sound becomes louder

and longer as this process repeats, giving the sound

a nice full timbre.

It is necessary to draw special attention to the solidity

of the wood used to make the neck, because this area

may bend under pressure while the instrument is being

tuned. The pear tree is the best for making pegs.

Pear wood pegs sustain the atmospheric pressure better

and stay in tune.

The strings are made of metal, kapron, silk or animal

gut. Metal strings produce the strongest and clearest

sound. However, they are much more difficult to press

with the fingers than silk or gut strings are. The

thickness of the strings depends on the individual

instrument. The loops on the ends of these strings

(photo) are inserted into the tailpiece on the lower

lateral part of the body. The tailpiece is made of

metal, ebonite or another firm wood.

The instrument-making traditions established in Azerbaijan

by talented craftsmen in olden times are still alive

today and are followed by dozens of contemporary professional

and skillful instrument makers. |